Main needs identified:

It was designed the need SF – FL product according to the properties of DHA2 sample.

| Basic Characterization DHA2 | ||

| °API @60°F | 18.8 | |

| BS&W [% v/v] | 0.2 | |

| Viscosidad [cSt] | 985 @90°F | |

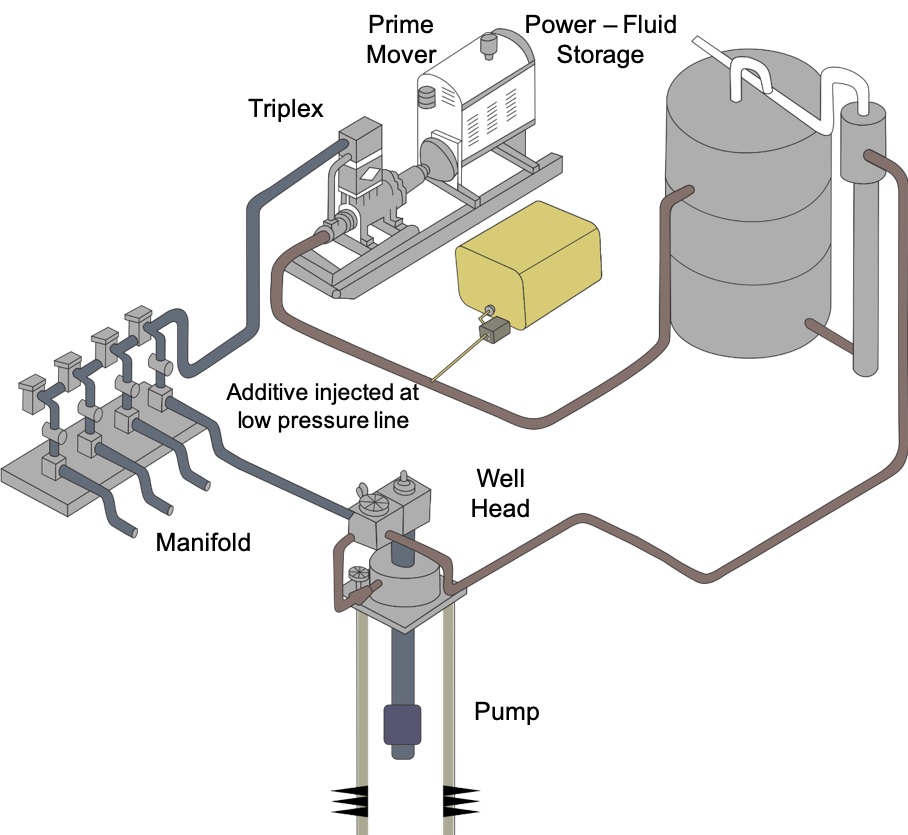

Bottom Hole SF – FL Fluidifier Application Through Low Pressure Line

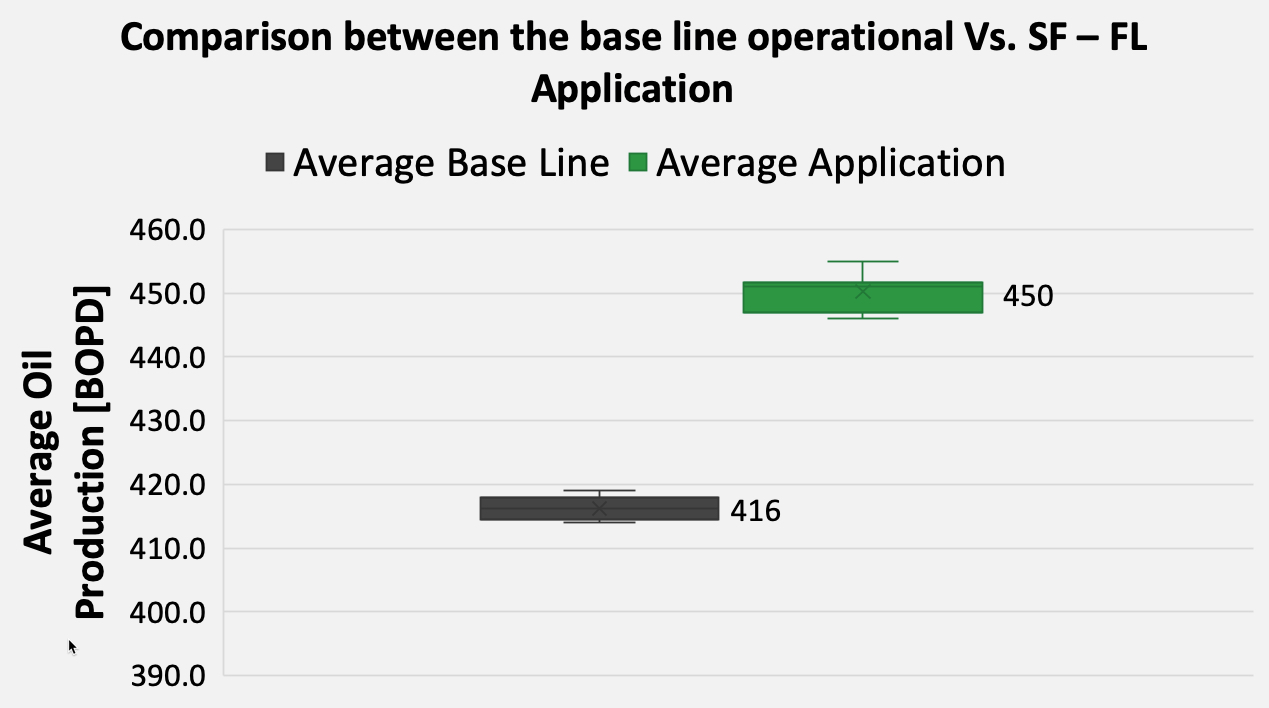

Benefits from the Application on ALS - HP

The Fluidifier additive showed to be compatible with the processing facility installed.