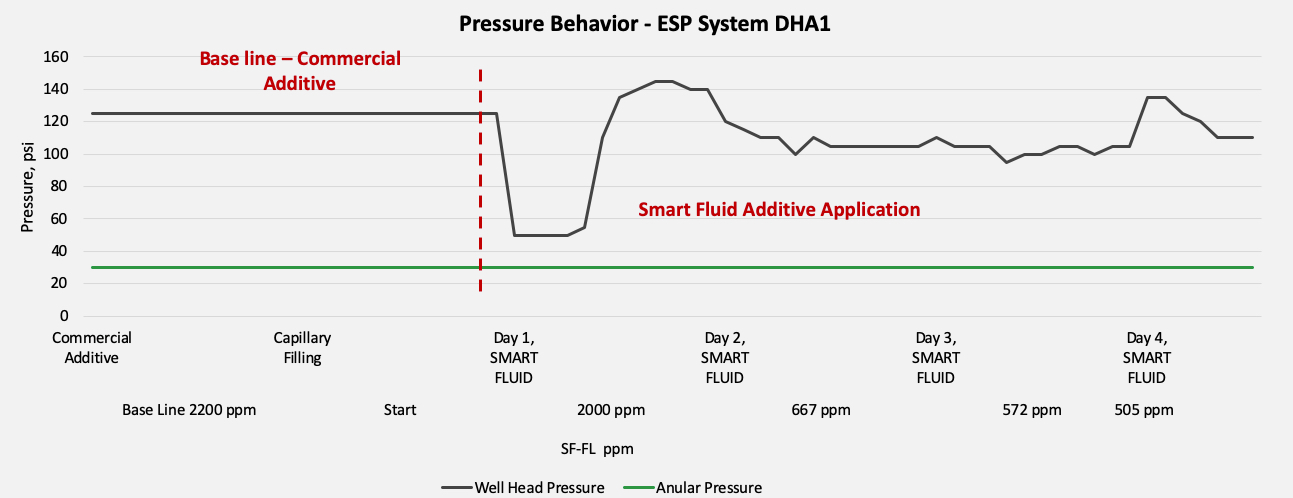

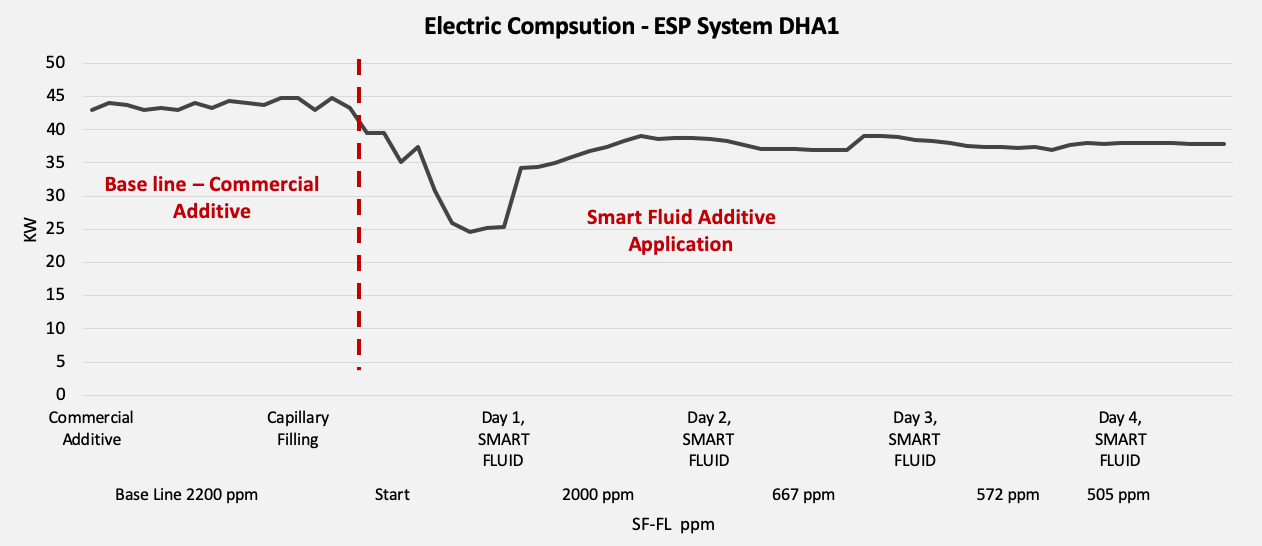

Identified needs for this application of additive in well with ALS – ESP

Bottom Hole SF – FL Fluidifier Application Through Capillary Injection

Benefits from the bottom hole application

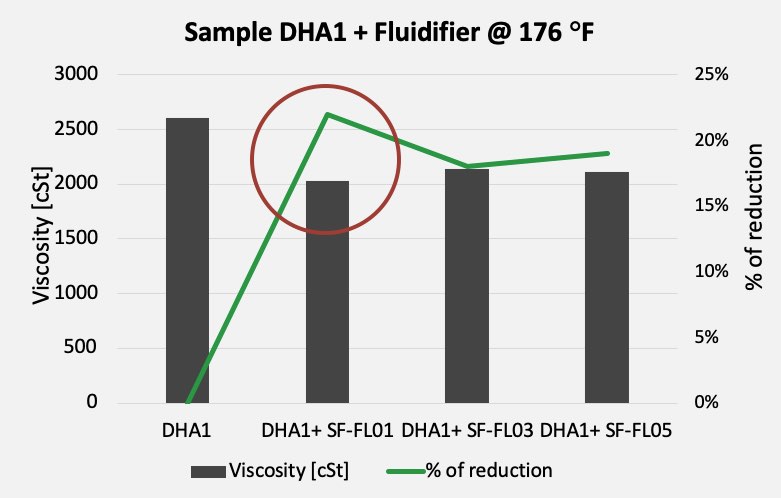

It was designed the need SF – FL product according to the properties of the DHA1 sample.

| Caracterización Básica DHA1 | ||

| °API @60°F | 12.7 | |

| BS&W [% v/v] | 8.8 | |

| Viscosity [cSt] | 2604@176°F | |

.png)